About Us

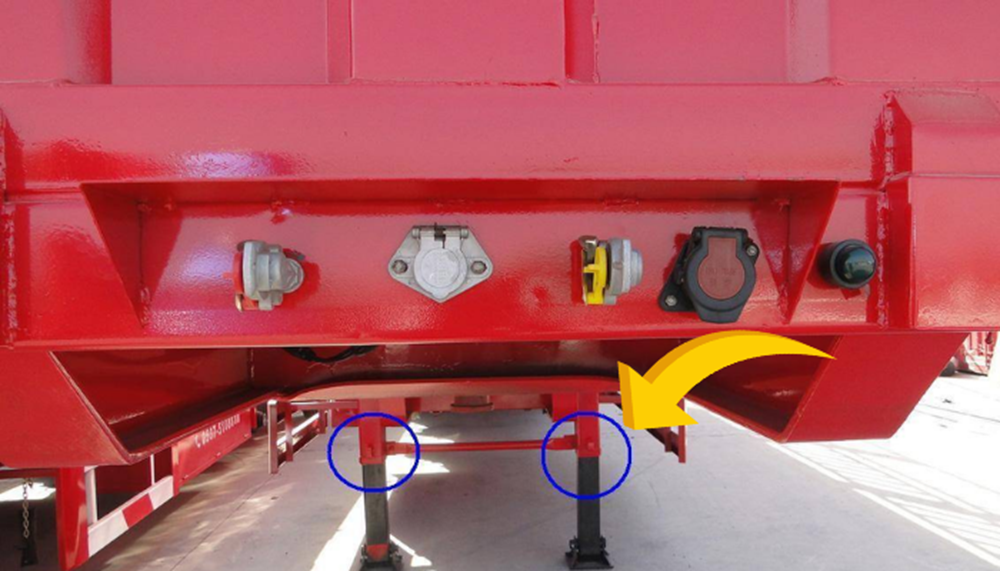

Do you understand truck outriggers? Have you clarified their uses?

Views : 367

Update time : 2025-06-19 16:00:00

I. Definition and Structural Types of Truck Outriggers

Truck outriggers are auxiliary supporting devices installed on the truck chassis. They form a stable supporting surface by contacting the ground and bear the vertical load when the vehicle is stationary. Their core components consist of support columns, telescopic mechanisms, bases and control systems. According to the driving methods, they are divided into three categories:

- Mechanical Manual Outriggers

Driven by screw rods and operated by a hand crank, they can bear a load of 5-15 tons. With a simple structure but time-consuming operation, they are commonly used in light trucks.

- Hydraulic Automatic Outriggers

Driven by a hydraulic pump station and controlled by solenoid valves for lifting, they can bear a load of 20-100 tons. Featuring fast lifting speed and high precision, they are widely used in semi-trailers and special vehicles.

- Pneumatic Outriggers

Driven by compressed air, they have a response speed of 0.3-0.5 seconds per time, with a load-bearing capacity of ≤10 tons, suitable for lightweight van trucks.

II. Core Functions and Technical Characteristics

(一) Three Core Functions

- Load Support

During loading and unloading, outriggers transfer the vehicle weight to the ground. For example, the outriggers of a 13-meter semi-trailer can bear 60% of the vertical load (30-40 tons), protecting the tire pressure stability.

- Anti-tip Stability

By expanding the support base distance (4-6 meters) and lowering the center of gravity (30-50 cm), the anti-roll capability is increased by 2-3 times.

- Horizontal Adjustment

Hydraulic outriggers are equipped with an automatic leveling system, which can calibrate the vehicle body within a ±3° slope, with a position accuracy of ≤2mm.

(二) Key Technical Comparisons

Hydraulic outriggers are made of high-strength alloy steel (yield strength ≥690MPa), with a telescopic stroke of 600-1200mm and a working temperature of -25℃~+80℃. Mechanical outriggers are mostly made of ordinary carbon steel (yield strength ≥345MPa), with a stroke of 300-600mm, adapting to the environment of -10℃~+60℃.

III. Application Scenarios

- Logistics and Transportation

When the semi-trailer is engaged in drop and pull operations, the outriggers support the trailer separated from the tractor, ensuring the safety of loading and unloading. For example, with outriggers, a container transport vehicle can complete the container replacement within 30 minutes, increasing the efficiency by 50% compared with the traditional method.

- Engineering Operations

The outriggers of concrete pump trucks can bear the overturning moment of 200 ton·meters when the boom is fully extended (56 meters).

- Municipal Emergency

Vehicles such as power supply vehicles can complete the support preparation within 2 minutes through the automatic leveling of hydraulic outriggers, meeting the timeliness requirements of emergency response.

IV. Safety Operation and Maintenance Points

(一) Operation Specifications

- Before use, check that the contact area of the outrigger base is ≥0.25㎡. The hydraulic system oil must comply with the ISO VG 46 standard, and preheat for 5-10 minutes at low temperatures.

- During operation, monitor the pressure (16-20MPa). It is forbidden to transfer the load when the outriggers are not fully deployed (angle <90°).

(二) Maintenance Cycles

- Daily: Check the hydraulic oil level and lubricate the screw rods.

- Quarterly: Replace the hydraulic oil and check the gear clearance.

- Annual: Clean the oil tank and replace the aging components.

V. Technical Development Trends

- Intelligence

Integrate sensors and IoT platforms for remote monitoring and fault early warning, with a diagnostic accuracy of over 95%.

- Lightweight Design

Adopt aluminum alloy and carbon fiber composite materials, reducing the weight by 30-40%.

- Energy Conservation and Environmental Protection

The electric hydraulic system reduces energy consumption by 40%, complies with the EU Stage V standard, and is expected to account for 60% of the market share by 2025.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.